Design thinking and communication

Jump to navigation

Jump to search

Contents

- 1 Uses of 2D and 3D sketching and digital tools

- 2 4.1a Demonstrate an understanding of how to use annotated sketching and digital tools to graphically communicate ideas and sketch modelling to explore possible improvements, in terms of physical requirements, such as:

- 3 4.1b Demonstrate an understanding of methods used to represent systems and components to inform third parties, such as:

- 4 4.2a An understanding of how designers develop products using digital tools and online collaboration, including:

- 5 4.2b An understanding of how digital design software is used during design development, including:

- 6 4.3a. Awareness of different strategies, techniques and approaches to explore, create and evaluate design ideas, including:

- 7 4.3b. The importance of collaboration to gain specialist knowledge from across subject areas when delivering solutions in the design and manufacturing industries

- 8 4.3c. Understand how design teams use different approaches to project management when faced with large projects

Uses of 2D and 3D sketching and digital tools

- Engineering drawing and artistic types of drawing, and either may be called simply "drawing" when the context is implicit. Engineering drawing shares some traits with artistic drawing in that both create pictures. But whereas the purpose of artistic drawing is to convey emotion or artistic sensitivity in some way (subjective impressions), the purpose of engineering drawing is to convey information (objective facts).

4.1a Demonstrate an understanding of how to use annotated sketching and digital tools to graphically communicate ideas and sketch modelling to explore possible improvements, in terms of physical requirements, such as:

- Function, usability, construction, movement, stability, composition, strength.

- When developing ideas you will need to discuss the following:

- The functionality, how does the project work, how does it solve the users needs and wants?

- Usability, how easy is the product to use, if the user group finds it difficult to operate, then it will need to be re-designed.

- Construction, how is the product put together, is it glued, welded, screwed together for example?

- Movement, how will any movement be achieved? Will it use any mechanisms for example?

- Stability, will it be able to repeat the tasks without any hinderance or issues?

- Composition, what materials are used to make the product and are they suitable?

- Strength, are the materials you have used strong enough to withstand any forces applied?

- Aesthetic qualities

- As a consumer, most of us are very interested in the way the product looks, have you taken into account what the users would like to see in the product and what they would like it to look like?

- Manufacturing processes. Have you considered the options available to manufacture the parts as well as the entire product, for example:

- One-off manufacturing,

- Injection moulding,

- JIT manufacture.

- These are discussed further in principle 7.

- Suitability of materials and components. Have you discussed the suitability of all the components and materials you have chosen for your product?

- For example, have you decided to use Gold for all the part, this would not be suitable due to its' high costs, or Have you used high power transistors when you only need a low power one?

4.1b Demonstrate an understanding of methods used to represent systems and components to inform third parties, such as:

Constructional diagrams/working drawings

- Constructional diagrams/working drawings are produced as engineering drawings. These are more than merely the drawing of pictures, it is also a graphical language that communicates ideas and information from one mind to another.

Digital visualisations

- Digital visualisations are any techniques for creating images, diagrams, or animations to communicate a message. Visualization through visual imagery has been an effective way to communicate both abstract and concrete ideas since the dawn of humanity. Examples from history include cave paintings, Egyptian hieroglyphs, Greek geometry, and Leonardo da Vinci's revolutionary methods of technical drawing for engineering and scientific purposes.

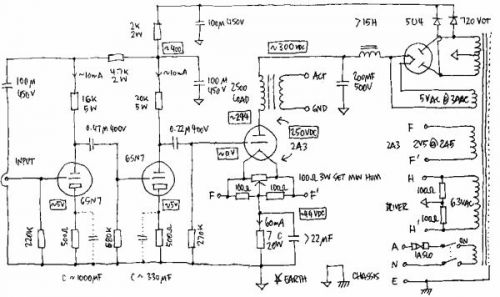

Circuit and system diagrams

- A circuit diagram (electrical diagram, elementary diagram, electronic schematic) is a graphical representation of an electrical circuit.

System Diagrams

- These are models used to visually express the dynamic forces acting upon the components of a process and the interactions between those forces. System Diagrams are more than process flow charts.

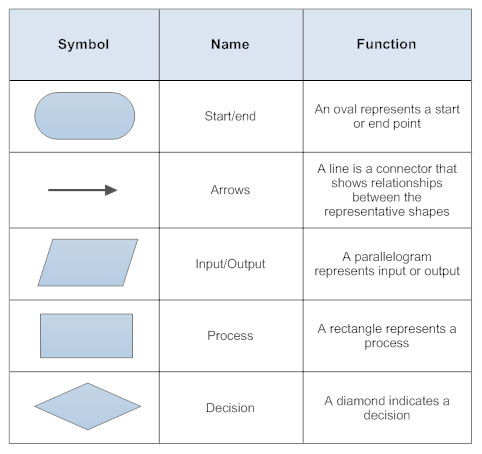

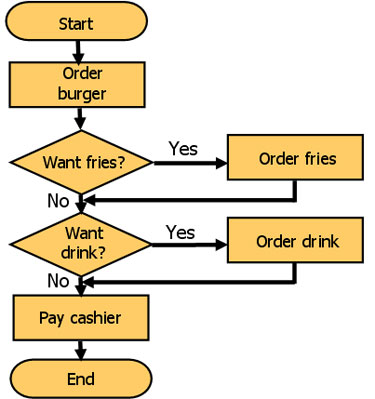

Flowcharts with associated symbols

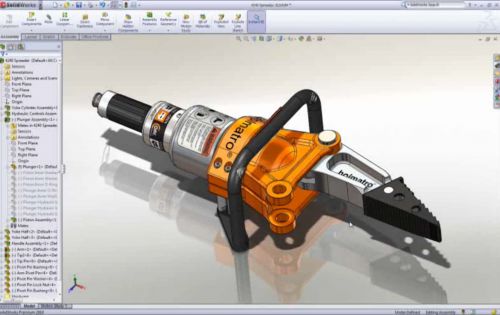

prototypes and models

- All of your products will have been prototype modelled in SolidWorks.

- Industry professionals use digital design tools to support and communicate the exploration, innovation and development of design ideas?

- Digital tools enable designers to visualise, develop ideas and communicate with their clients more easily, sharing ideas and information using cloud platforms, online forums and e-mail.

- This is turn is making design a more collaborative process as it enables designers, engineers, manufacturers and stakeholders to have an easy input into the design process.

4.2a An understanding of how designers develop products using digital tools and online collaboration, including:

- Discussing and exchanging ideas with specialists.

- Developing designs concurrently with other designers.

- Explaining and communicating their design decisions to stakeholders.

4.2b An understanding of how digital design software is used during design development, including:

Visual presentation, rendering and photo-quality imaging

- Visual presentations are:

- An efficient and quick way of telling the story of manufacture.

- A good way to allow audiences to absorb the information without the product being shown.

- An effective visualisation, graphic or image based communication method to display you product.

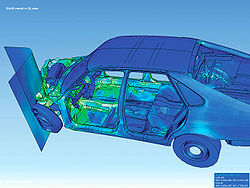

Product simulation and systems simulation

- Simulation is the imitation of the operation of a real-world process or system over time. The act of simulating something first requires that a model be developed; this model represents the key characteristics, behaviors and functions of the selected physical or abstract system or process. The model represents the system itself, whereas the simulation represents the operation of the system over time.

Scientific analysis of real-world physical factors

- These can be used to determine whether a product will break or work the way it was intended.

- The scientific analysis method is a body of techniques for investigating phenomena, acquiring new knowledge, or correcting and integrating previous knowledge. To be termed scientific, a method of inquiry is commonly based on empirical or measurable evidence subject to specific principles of reasoning.

- Design engineers use different approaches to design thinking to support the development of design ideas?

4.3a. Awareness of different strategies, techniques and approaches to explore, create and evaluate design ideas, including:

Iterative designing

- Iterative design is a design methodology based on a cyclic process of prototyping, testing, analyzing, and refining a product or process. Based on the results of testing the most recent iteration of a design, changes and refinements are made. This process is intended to ultimately improve the quality and functionality of a design. In iterative design, interaction with the designed system is used as a form of research for informing and evolving a project, as successive versions, or iterations of a design are implemented. E.g. When developing a new laundry machine, engineers might undertake...

- Rigorous, recurring and progressive testing, modelling and development, with user feedback’ of prototype solutions helps to achieve the fit for purpose outcome.

- The design would be modelled in a development area, using the actual valve and cylinder components to test that the air pressures and forces generated are sufficient to overcome friction and operate the water inlet valve. This will identify any required modifications to improve the design solution.

- User testing and location testing can be used at throughout the process to obtain feedback that identifies where the user foresees issues with the system. This will lead into consideration of modifications in line with stakeholder requirements.

- CAD could be used to model the entire system before manufacture of parts or assembly of system components. This allows clearances to be checked and distances to be finalised before final fitting on site.

- The modelled system can be soak tested, i.e. continually cycled for several thousand operations to generate a rough idea of system life expectancy. The outcomes from this testing can be analysed to identify areas of improvement that need to be made in future iterations of the product development.

- The software for the controller can be developed, debugged and tested with the user before installing into the laundry system. User feedback can be very useful for further developing the solution.

User-centred design

- User-centered design (UCD) or user-driven development (UDD) is a framework of processes (not restricted to interfaces or technologies) in which usability goals, user characteristics, environment, tasks and workflow of a product, service or process are given extensive attention at each stage of the design process.

- User-centered design can be characterized as a multi-stage problem-solving process that not only requires designers to analyze and envision the way users are likely to consume a product, but also to validate their assumptions with regard to the user behavior in real world tests.

- These tests are conducted with/without actual users during each stage of the process from requirements, pre-production models and post production, completing a circle of proof back to and ensuring that "development proceeds with the user as the center of focus." Such testing is necessary as it is often very difficult for the designers of a product to understand intuitively what a first-time user of their design experiences, and what each user's learning curve may look like.

Circular economy

- A circular economy is a regenerative system in which resource input and waste, emission, and energy leakage are minimised by slowing, closing, and narrowing material and energy loops. This can be achieved through long-lasting design, maintenance, repair, reuse, remanufacturing, refurbishing, and recycling. This is in contrast to a linear economy which is a 'take, make, dispose' model of production.

Systems thinking

- Critical systems thinking is a systems thinking framework that wants to bring unity to the diversity of different systems approaches and advises managers how best to use them.

- Critical Systems Thinking "aims to combine systems thinking and participatory methods to address the challenges of problems characterised by large scale, complexity, uncertainty, impermanence, and imperfection. It allows nonlinear relationships, feedback loops, hierarchies, emergent properties and so on to be taken into account and Critical Systems Thinking has particularly problematised the issue of boundaries and their consequences for inclusion, exclusion and marginalisation".

4.3b. The importance of collaboration to gain specialist knowledge from across subject areas when delivering solutions in the design and manufacturing industries

- There are many good reasons to collaborate with others with specialist knowledge to develop a product, here are some of the positives:

- Enable quick and effective decision-making

- Facilitate research and access to relevant information and resources

- Reuse ideas, experiences and expertise

- Avoid redundant efforts

- Avoid making the same mistake several times

- Take advantage of existing experiences and expertise

- Communicate widely and quickly important information

- Promote and rapidly deploy reproducible standards, procedures and processes

- Provide methods, tools, templates, techniques and examples

- Ensure that scarce expertise is widely disseminated

- Show clients how knowledge can be used and the benefits that can be gained

- Accelerate delivery times for customers

- Allow the organization to take advantage of its size

- Make the organization the champion of reusing experience to solve its problems

- Stimulate innovation and development

- To read more about these, click on this link.

Collaboration - EXAMPLES

- During the design phase of a product

- Diverse Expertise: Complex systems often require expertise from multiple disciplines such as mechanical engineering, electrical engineering, software engineering, and more. Collaboration allows engineers with different specialties to contribute their unique skills and knowledge to address various aspects of system design, ensuring a comprehensive and well-rounded approach.

- Holistic Problem-solving: Complex systems typically involve interconnected components and subsystems, each with its own requirements and constraints. Collaboration enables engineers to take a holistic approach to problem-solving, considering the interactions and dependencies between different parts of the system and finding solutions that optimize overall performance and reliability.

- Innovation and Creativity: Collaboration fosters an environment where ideas can be shared, challenged, and refined collectively. By collaborating with peers, engineers can leverage each other's creativity and insights to explore new concepts, innovative design approaches, and novel solutions to complex engineering problems, leading to breakthrough innovations and advancements in technology.

- Adaptability and Flexibility: An acknowledgement that complex systems often evolve over time due to changing requirements, technological advancements, or external factors. Collaboration enables engineering teams to adapt and respond to these changes more effectively by fostering a culture of flexibility, open communication, and continuous learning, allowing the system to remain relevant and resilient in the face of evolving challenges.

- User Need Assessment: The collaboration between the designer and engineer begins during the user need assessment. With both parties consulting with professionals in other fields (e.g. medical, aeronautical), users and other stakeholders, they are able to identify key requirements prior to the design process.

- Concept Development and Technical Feasibility: Designers are likely to generate initial concepts and prototypes based on the information gathered in the User Needs Assessment. Concurrently, engineers would have assessed the technical feasibility of the proposed designs considering factors such as material selection, manufacturing processes and regulatory requirements. They will also be needed to ensure that the product meets the necessary performance standards while remaining practical for it’s intended purpose.

- Prototyping and testing

- Testing: During this phase the designers and engineers will create the prototype together, testing each element and ensuring that the ergonomics and ease of use are upmost. Feedback from professionals in other fields (e.g. scientists, medical, military) with give informed decisions for the engineers and designers to produce new iterations.

- Risk Mitigation: Complex systems carry an inherent risk such as technical failure, safety hazards and costs. Collaboration will reduce the risk by identifying issues early.

- Quality Assurance: An understanding that collaboration facilitates peer review and feedback, allowing engineers to validate their designs, identify potential flaws or deficiencies, and make necessary improvements before finalising the system. This iterative process of review and refinement helps ensure that the system meets quality standards, regulatory requirements, and customer expectations.

- Manufacturing and production

- Manufacturing Methods: Once a design has been finalised, engineers will work closely with both designing and the manufacturing engineers to oversee the production process. They would ensure that the manufacturing methods and quality control measures were in place to produce the product.

- Efficiency and Productivity: Through collaboration engineers are able to play to others strengths and resources more effectively. By dividing individual tasks and sharing workload engineers would be able to decrease timelines and reduce costs.

- Regulatory Compliance: Throughout the development process, designers and engineers would have collaborated to ensure that the new product complies with the relevant standards and certifications.

4.3c. Understand how design teams use different approaches to project management when faced with large projects

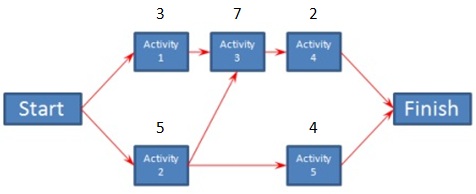

Critical path analysis

- Critical Path Analysis (CPA), also known as the Critical Path Method (CPM), is a project management technique that identifies the most crucial tasks within a project and determines the shortest possible completion time. It helps project managers allocate resources, monitor progress, and ensure timely completion by focusing on the longest sequence of dependent activities, known as the critical path.

- Here's a more detailed explanation:

- Identifying Critical Tasks: CPA involves listing all project activities, identifying dependencies between them, and estimating the duration of each task.

- Creating a Network Diagram: These activities are then visually represented in a network diagram, showing the sequence and dependencies.

- Determining the Critical Path: The longest sequence of dependent activities, where any delay would directly impact the project completion date, is identified as the critical path.

- Analysing Float: CPA also helps identify activities with "float" or slack, meaning they can be delayed without affecting the project timeline.

- Resource Allocation and Monitoring: Understanding the critical path allows for efficient resource allocation and monitoring of critical tasks, ensuring the project stays on track.

- Benefits of Critical Path Analysis:

- Determines Minimum Project Duration: It helps establish a realistic deadline and target completion time.

- Prioritizes Tasks: It highlights the most important tasks that need constant monitoring and focus.

- Facilitates Resource Allocation: It helps allocate resources effectively by identifying critical and non-critical activities.

- Improves Project Control: It provides a clear framework for managing project dependencies and potential risks.

- Enhances Communication: The network diagram provides a visual representation of the project schedule and dependencies, facilitating communication among team members.

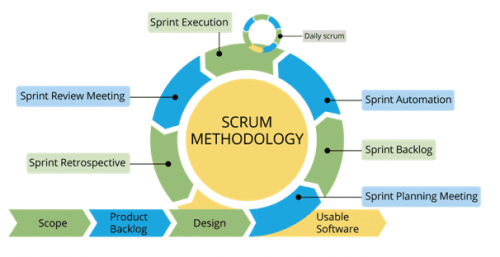

Scrum

- Scrum is an Agile project management framework that enables teams to work collaboratively and efficiently to deliver products iteratively and incrementally. It focuses on iterative development, continuous feedback, and adaptive planning, allowing teams to respond effectively to changes and uncertainties.

- Key aspects of Scrum include:

- Iterative and Incremental Development: Work is broken down into small, time-boxed iterations called sprints, typically lasting two to four weeks.

- Daily Scrum (Stand-up): Short, daily meetings where the team discusses progress, challenges, and plans for the day.

- Sprint Planning: The team selects tasks from the product backlog for the upcoming sprint and determines how they will be completed.

- Sprint Review: At the end of each sprint, the team demonstrates the completed work to stakeholders and gathers feedback.

- Sprint Retrospective: The team reflects on the past sprint, identifies areas for improvement, and plans for the next sprint.

- Roles: Scrum involves key roles like the Product Owner (responsible for maximizing product value), Scrum Master (facilitator for the team), and the Development Team (responsible for delivering the product).

- Artifacts: Scrum uses artifacts like the Product Backlog (a prioritized list of features), Sprint Backlog (a list of tasks for the current sprint), and the Increment (the potentially shippable product delivered at the end of each sprint).

- Scrum's flexibility and iterative approach make it well-suited for projects where requirements may evolve or where the project scope is not fully defined at the outset. It promotes continuous improvement and helps teams deliver value to stakeholders throughout the project lifecycle.

Six Sigma

- Six Sigma is a data-driven methodology for improving business processes by reducing defects and waste. It's particularly effective in project management by focusing on improving quality, efficiency, and customer satisfaction through process optimization and variation reduction. Six Sigma project managers leverage statistical tools, financial analysis, and project management principles to identify and address root causes of issues.

- Key Aspects of Six Sigma in Project Management:

- DMAIC Framework: Six Sigma projects typically follow the DMAIC framework: Define, Measure, Analyze, Improve, and Control.

- Focus on Variation Reduction: Six Sigma aims to reduce variation within processes to minimize defects and improve consistency.

- Customer Focus: Six Sigma projects prioritize understanding and meeting customer needs.

- Data-Driven Approach: Six Sigma relies heavily on data analysis to identify problems and track improvements.

- Process Improvement: Six Sigma focuses on improving existing processes, rather than creating new ones.

- Lean Six Sigma: Combining Six Sigma with Lean principles can further optimize processes by eliminating waste and improving efficiency.

- Training and Certification: Six Sigma practitioners undergo training and often achieve certification in various levels, such as Yellow Belt, Green Belt, and Black Belt.

- Financial Benefits: Six Sigma projects often yield tangible financial benefits by reducing costs, improving quality, and increasing customer satisfaction.

- Complementary to Project Management: Six Sigma can be integrated with other project management methodologies, such as Agile or Waterfall, to enhance project success.

- Real-World Examples: Six Sigma has been successfully implemented in various industries, including manufacturing, healthcare, and finance.